固定點

更新計畫

REBOLTING

PROJECT

攝影 © 楊宗穎 | Michael Yang

龍洞的錨栓更新工作 (Rebolt) 已行之有年,初期僅由少數資深岩友自主更新,直到章醫師於2010年發起「龍洞Rebolt計畫」,才開始有系統、大規模地更新。剛開始時,只有章醫師和少數資深前輩犧牲自己的假期默默為大家工作,但隨著更多岩友加入,更多的人力、知識、與技術不斷投入,這個計畫也逐漸發展出更全面的錨栓更新方案,並凝聚出「永續龍洞」的重要精神,進而發展出錨栓資訊普查、老舊錨栓移除/更新、拉力測試計畫、洗洞計畫、臺灣自製鈦合金錨栓計畫、建立路線資料庫等工作,其背後最重要的宗旨,就是為了盡可能減少在岩壁上鑽孔,同時將目前現有的錨栓使用年限最大化,以達到「永續龍洞」的精神。而這些繁雜的工作,是由許多人貢獻寶貴的知識和時間,經歷過無盡的辯論所堆砌而成的成果,像這樣全面而深入的錨栓維護方案,也是全球所有天然岩場中極為罕見的。

Rebolting at Long Dong has been ongoing for many years. In the beginning, the job of bolt replacement was done by a few climbers on a spontaneous, voluntary basis. Then, in 2010, Dr. Chang initiated the “Long Dong Rebolting Project,” which brought into effect a more systematic and comprehensive approach on a broader scale. In the first years of the Rebolting Project, there were still only a few climbers involved, dedicating their free time to replace bolts and maintain the safety of Long Dong routes, their hard work unbeknownst to most climbers. But as more and more people became involved, the Rebolting Project evolved into a more knowledge-based project, which instilled a sense of esprit de corps among Long Dong climbers working together on sustainable development at Long Dong based on a set of standardized procedures: surveying all existing bolts, removing and replacing bolts, performing pull tests on existing bolts, core-drilling old bolts, procuring Taiwan-made titanium bolts, and establishing a comprehensive database that includes key data on all bolts on all routes at Long Dong. These activities are carried out with the goal of minimizing new holes by using existing bolts as long as safely possible, thereby attaining a sustainable Long Dong. Such an encompassing, comprehensive, manpower-intensive, resource-consuming and volunteer-based project represents a community effort that is quite unique and indeed very special among the local climbing communities around the world.

錨栓普查

BOLT

INVESTIGATION

由資深岩友游金龍於 2010 年發起,號召岩友搜集龍洞岩場每條路線上每一支錨栓的相關資訊,如廠牌、型號、款式、材質、設置時間等,將所有路線與錨栓相關資訊彙整統計,製成有史以來最詳盡的龍洞路線資料庫,並即時更新,以便日後供岩友與工作人員查詢。

In 2010, Long Dong climber Jinlung You began contacting route developers and bolters to collect information about bolts they had installed or knew about. The information gathered, including bolt brand, type. model, material and date of installation, was accumulated into Long Dong Route/Bolt Database. This database, accessible to the public, is kept up to date whenever route or bolt maintenance takes place, and comprises an invaluable resource for reference by volunteers and climbers alike.

2009

目前已追蹤的龍洞錨栓總量為

A total of bolts are being monitored:

111

304 stainless steel bolt

1276

316 stainless steel bolt

Titanium bolt

622

自 2019 年開始,除了錨栓之外,我們也將路線上方固定點 (Top anchor) 的附掛配件,如梅龍鎖、羊角、垂降鋼環等,一併納入追蹤統計資料中,並且也將少數傳攀路線的天然固定點,以及救援計畫專用的上方固定點,正式編入定期巡查維護清單中,然而,由於資訊量龐大且繁複,因此,若各位發現資料有誤時,還請不吝提供正確資訊,我們將盡快改正。

In 2019 the survey was expanded slightly to include the hardware attached to top anchor bolts, such as quicklinks (aka maillon rapide or maillons), ram’s horns, and rings, and the database was expanded to include notes about their functionality or ease of use. Also now included are natural anchors, i.e., not bolts but natural features that have been rigged (with rope, for example) for use as anchors, as well as the rescue anchors that were installed specifically for rescue purposes. This database represents a huge amount of information to be recorded and managed, and some errors or omissions may occur. If you notice any such error, please let the TOCC know so that we can rectify it accordingly.

錨栓更新

DEBOLT

&REBOLT

由眾多岩友擔任志工組成工作團隊,目前由資深岩友游金龍與游健郎主導,負責老舊錨栓的移除,以及新錨栓的設置作業。

This project aims to remove bolts at Long Dong deemed no longer reliable and replace them with modern bolts of suitable materials. The project team comprises many volunteer climbers, led by veteran climbers Jinlung You and Jian-Lang You.

由於龍洞為濱海岩場,嚴苛的氣候無時無刻都在考驗著這裡的金屬設備,而為了降低岩友對於應力裂隙腐蝕 (Stress Corrosion Cracking) 的疑慮,在經過多年努力後,我們終於將龍洞大部分區域的 304 不鏽鋼錨栓全數移除更新,目前僅剩第一洞較高難度或較難施工的路線仍有少量殘留 (部分路線已掛上警告布標),因此,除了持續追蹤外,我們也會盡快安排人力將這些堪慮的錨栓移除並更新。

Being comprised of sea cliffs, Long Dong has witnessed stress corrosion cracking (SCC), which has occurred in bolts made of 304-grade stainless steel, but has not been observed in 316-grade stainless steel bolts. Hence almost all 304-grade bolts have been removed (and replaced with either 316-grade stainless or titanium bolts), except for a few remaining 304-grade bolts in First Cave, wherein the routes having 304-grade bolts are generally marked with warning tags on their first (lowest) bolts, and which are slated for removal and replacement as soon as possible.

2021

工作重點目標

Plans and Goals

-

持續進行必要的錨栓更新作業

-

移除第一洞少數殘餘的 304 不鏽鋼錨栓

-

熱門路線 Anchor Bolt 加裝 316 不銹鋼梅龍鎖 (Mallion Rapide) 與垂降環

-

持續招募 / 訓練志工擴大團隊,提昇整體工作速度

-

Continue to remove and replace bolts identified for replacement;

-

Remove and replace bolts in First Cave;

-

Add quicklinks (maillon rapide) and rappel rings to the top anchors of popular routes;

-

Recruit and train more volunteers, in order to accelerate all work in progress and improve overall project efficiency.

拉力測試計畫

PULLTEST

PROJECT

由資深岩友康明哲、吳彥儀、游金龍於2016年發起。參考工業標準,以拉力測試機對受測錨栓施以 8 kN 軸向拉力 1 分鐘,並重複施以 5 次測試,藉此監測每支錨栓的自身強度與施工品質 (化學膠強度),確保岩壁上的每支錨栓都能正常使用。

In accordance with international industrial standards, Kant Kang, Yan-Yi Wu, and Jinlung You designed the pull test in 2016. The pull test includes applying an axial (pull) force of 8 kN to a bolt for one minute, and then repeating this 5 times, to test the strength of the bolt and its glue, in order to confirm that the bolt can function properly when used by climbers.

拉力測試,是工程界常見的一道檢測工序,通常稱為「地錨揚起試驗」,定期對施工用錨栓進行抽樣拉力測試,一般以設計強度 1.1–1.3 倍做為測試時的加載原則,以確保錨栓並未因腐蝕或其他因素而使其強度低於安全使用標準。在綜合考量龍洞岩場的可執行性與客觀參考數據後,目前我們的測試方法為:以拉力測試機施以 8kN 拉力,持續 1 分鐘,並在 10 分鐘內重複測 5 次。通過條件為抗拉力與彈性變化皆符合降伏強度內之表現 (測試時持續維持加載負荷,是為了等待變位穩定,一般為 1 分鐘)。

目前測試合格的不鏽鋼錨栓,其降伏強度應大於 8kN,而極限強度 (破壞強度) 沒有測試,但以降伏強度的 1.5 倍估計,應大於 12kN。若想了解更多拉測相關資訊,可參閱 拉力測試 FAQ。

The pull test is the equivalent to the well-known “ground anchor lift-off test” used in the construction industry. The ground anchor lift-off test includes pulling a sample of ground anchors with an increasing force until a maximum pulling force of 1.1 to 1.3 times the original design force is reached. At Long Dong, due to various safety considerations and to avoid the possibility of compromising a well-placed and properly-functioning bolt by applying the maximum force of the bolt design, the pull test instead uses a force of 8 kN to test the bolt (that is, the maximum-force, or breaking-strength, test is not performed on bolts at Long Dong, because the test is performed on actual in-situ bolts). The 8 kN force on the bolt is maintained for one minute and the entire process is repeated 5 times over a 10-minute period. The purpose of maintaining an 8 kN force one minute on a bolt is to watch for any indication of weakening of the bolt’s yield strength while the force is applied. If so, then the bolt needs to be examined and replaced; if not, then the bolt is determined to have an axial yield strength of at least 8 kN, which corresponds to a radial strength (resistance to shear force) of at least 12 kN. This is acceptably strong for climbing application, including holding the force of a lead fall. For more information, please refer to the Pull Test FAQ.

本計畫選用的設備,為英國 Hydrajaws Limited 所生產的 Model 2000 Safety Harness Eyebolt & Ringbolt Tester 固定點拉力測試機,普遍應用於工業繩索作業 (Rope Access) 領域,專門用來進行固定點拉力測試之用,體積小、重量輕,且架設方便迅速,可說是目前國際上市售類似設備中最適合進行高空拉力測試用的機型。

拉力測試機

PULLTESTER

然而,原既有拉測機在長期大量使用後開始出現狀況,加上拉測小組持續有新血加入,開始能安排更多人力同時作業,故本著備用機與雙機作業提高效率的動機,岩友一樵老爹以及小曼特捐贈專款加購,並由老爹利用出差機會親自從英國帶回一台全新的同款拉力測試機以供拉測作業之用,同時也將舊機與測壓錶一起帶回英國原廠,進行了一次徹底檢修與校正,以維持拉測數據的準確性。

The pull test employs Model 2000 Safety Harness Eyebolt & Ringbolt Tester, made by Hydrajaws, Ltd.. This model has been commonly used by the rope access industry to evaluate the anchors, and is one of the most compact, lightest, and convenient-to-set-up-on-cliff models in this category.

2019

工作成效統計

Plans and Results

2019 年初,我們在進行了大部份運動路線的第一顆錨栓抽測,以及臺製鈦合金錨栓的品管拉測後,便開始將工作重心轉移到所有 316 不鏽鋼錨栓的拉測作業,其中包含了運動路線的全線拉測,以及傳攀路線與救援計畫專用的上方固定點;另外,少數傳攀路線使用的天然固定點也正式編入定期巡護更新的工作清單中。這一年的工作成果非常豐碩,也發現幾處有問題的錨栓並加以更新。這是龍洞岩場有史以來第一次透過檢測程序提早發現問題並在事前維修,避免可能因錨栓失效而導致意外的發生。經檢測程序而達到提早預警的功能,遠超出了我們預期的成效,也讓我們更加確信,錨栓的拉力測試確實可以對龍洞的攀登安全提供實際的效益,而這些事証的存在,或許也可消除少數對拉力測試感到存疑的岩友們心中的疑慮。

The beginning of 2019 saw the completion of two projects: performing pull testing on the first bolt of most sport routes at Long Dong, and completing quality testing of the entire batch of Taiwan-made titanium bolts (using a testing method similar to the pull test). After that, the project transitioned to testing all bolts (not merely first bolts) of routes equipped with 316-grade bolts (most 304-grade bolts had been removed and replaced with 316 bolts by that time). In addition, 316-grade anchor bolts on the top of some traditional lines were also tested. On some traditional routes without anchor bolts, natural anchors were installed, and scheduled for regular examination. This was the first time in Long Dong’s history that such extensive, systematic, and proactive steps to ensure safety of bolts and anchors had been taken. The efforts were fruitful: not only were a few questionable bolts discovered (see below), possibly preventing accidents, but also the practicality of the pull test was established, thereby providing reassurance to members of the climbing community who might have doubted the test procedures.

2019年檢測失敗的錨栓共3個,分別為:

黃金谷 傳奇岩 #152 名不虛傳 (運攀) - B05

黃金谷 浪之外 #124 橘子之旅 (運攀) - B03

鐘塔區 訓導處 #479 給我抱抱 (運攀) - B02

註:B05 = 自地面往上數第5個錨栓

這三個失效的錨栓經過判斷皆為施工不慎導致黏膠黏合不良所致,實際在拉測時拉力皆未達8kN即被拉力測試機拉出,並在測試作業結束後便在第一時間即由更新團隊完成更新作業。錨栓桿芯經目視觀察皆無任何銹蝕或變形的徵狀,而就整體結果來看,全年度抽檢的245支錨栓均無任何疑似因銹蝕導致強度降低的現象。

There were 3 bolts in total which failed the pull test during 2019

Golden Valley | Legend Wall #152 The Real Legend (Sport) - B05

Golden Valley | Euro Wall #124 Tangerine Trip (Sport) - B03

Clocktower | Discipline Area #479 Fal Buligee (Sport) - B02

Note: B05 = the 5th bolt from ground up.

The 3 bolts that failed the pull test all pulled out during the test due to the failure of the glue, not of the bolt itself, before the pulling force reached 8 kN. Close examination revealed no sign of corrosion or deformation on any of the 3 bolts. The pulled bolts were immediately replaced with titanium bolts. In total, 245 bolts were examined via the pull test in 2019, and apart from the 3 bolts mentioned above, no other bolts exhibited any reduction in strength.

2021

工作重點目標

Main Objective

-

持續進行各區所有 316 不鏽鋼錨栓監測工作 (包含運攀路線全線,以及傳攀路線 Top anchor)

-

天然固定點定期巡查更新 (每半年一次)

-

持續核對 / 更新錨栓資料,提昇資料準確性

-

熱門路線 Anchor Bolt 加裝 316 不銹鋼梅龍鎖(Mallion Rapide) 與垂降環

-

持續招募 / 訓練志工擴大團隊,提昇整體工作速度

-

Continue pull testing of all 316-grade bolts (testing all bolts on each route, including anchor bolts on traditional routes);

-

Check all natural anchors periodically (once every six months);

-

Continue to update and maintain the accuracy of the Long Dong Route/Bolt Database;

-

Continue to add quicklinks (maillon rapides) and rappel rings to top anchors of popular routes, if deemed necessary;

-

Recruit and train more volunteers, in order to speed up all work in progress and improve the project efficiency.

臺製鈦BOLT計畫

MIT

Ti BOLT

由資深岩友康明哲、吳彥儀、游金龍於2016年開發,是臺灣有史以來第一款由攀岩者自行設計研發,通過各項標準測試,並在經過 X 光孔隙率檢測與 12kN 拉力品管檢測後才正式使用的鈦合金錨栓,目前計畫已順利完成,所有通過檢測的臺製鈦合金錨栓正全面使用中。

The titanium bolt was developed jointly by senior climbers Kant Kang, Yan-Yi Wu, and Jinlung You in 2016. It is the first bolt to be designed by Taiwanese climbers, and first bolt to be made in Taiwan. Each titanium bolt must pass an X-ray interstice examination and a 12kN (axial) pull-test before being installed. All titanium bolts in stock have passed the aforementioned examination and test and are ready to be installed.

2015年七月底,音樂廳大鼓路線上方固定點的斷裂意外,敲響了下一波龍洞路線更新的警鐘。基於全球攀岩社群對應力裂隙腐蝕 (SCC) 的認知與文獻,以及大量的內部討論,選擇抗腐蝕性比 316 不鏽鋼更高的金屬材料,似乎是我們接下來的唯一方向,也是我們必須認真研究的第一道課題。然而,高抗腐蝕的金屬材料可不只有鈦一種,而鈦金屬於工業的應用上,更是區分成許多不同規格的合金配比。眾多岩友不斷地提供各種可能、建議與專業知識,從 HILTI 的經理到實驗室的研究員皆成了岩友們請益的對象。雖然我們無法採用所有人的建言,但岩友們所提供的各種建議,都協助我們得以做出更恰當的選擇;經過複雜的匯整、判斷與學習之後,自製鈦金屬bolt似乎是一個合理的方向。

臺灣本身就是金屬加工與製造王國,而目前龍洞實際使用上,除了少數他牌鈦合金錨栓之外,信賴度相對較高的,就是早期的臺製 316 錨栓。事實上這也是市場上的自然現象;一個商品能出現在市場上,其製造端成本絕大部分都不能超過零售價的三成,請注意,是「不能」,而不是「不會」。廠商生產商品需要負擔各種成本:風險、設計、測試、認證、庫存、行銷等,以及許多非關生產的開銷,同時,廠商還需要賺取利潤,而代理/經銷商、物流業者、以及零售商也都需要利潤,因此,同樣代價的鈦合金錨栓,從工廠直出的產品,其用料與耐久度自然會比市售的品牌錨栓更勝一籌。所以,只要我們能找到優良的工廠,以正確的程序研發製做,就有機會獲得品質更高、往後問題更少的bolt。

感謝原岩攀岩館館長鄭地瓜的努力,找到了一流的鈦合金加工廠 – 復盛應用科技股份有限公司。一家 2014 年台灣出口前 100 大,員工多達一萬一千人,已於汽車、醫療、航太等方面大量提供鈦合金精密製造服務的廠家。他們常規生產的鈦合金產品,包含了汽車渦輪葉片、高爾夫球桿頭、船用各式連接構件等,結構強度與品質都需到達高標的產品,製作攀岩用錨栓當然沒問題。

In late July, 2015, a rappel anchor on the top of the Music Hall route, Big Drum, failed, and that breakage rang a warning bell to the climbing community. Something needed to be done concerning the safety and perhaps the replacement of the existing stainless steel bolts. After numerous discussions and extensive research in the field of stress corrosion cracking (SCC), which is a type of insidious corrosion attacking stainless steel, it seemed that using materials that have corrosion resistance higher than that of 316-grade stainless steel could be the only option. There are many types of material that offer such high levels of corrosion resistance, including the most renown, titanium. But titanium alone has many different types of alloy due to different industrial applications. In any event, after consulting with personnel of Hilti and other experts and drawing upon many helpful opinions and advice from local climbers, it seemed that making and customizing titanium bolts on our own could be the most reasonable direction to take.

Taiwan is well known around the world for its high-quality manufacturing capability. Therefore, regarding climbing bolts, it is no surprise that among all bolts installed at Long Dong as of 2015, the most reliable ones were the Taiwan-made 316-grade stainless steel bolts, apart from a few titanium bolts sold by foreign manufacturers on the international market. This is easily understood by considering a very simple concept: cost consideration. We all know the way in which a market operates, that is, for any product sold on the market, the manufacturing cost should not be more than approximately 30% of the market price. Note that it’s ‘should not be’ but not ‘can’t be.’ This is because along the production and market chains, necessary costs are added in every step: design, risk, testing, certification, storage, marketing, etc., and on top of this, everyone involved must also make reasonable profits, i.e., the most important motivation, the so-called ‘invisible hand’ for a market even to exist. So, if we can drop the need of profit, that is to say, if we can spend an amount of money equivalent to the market prices of those marketed titanium bolts, we can then acquire higher quality titanium bolts, just as those Taiwan-made 316-grade stainless steel bolts have demonstrated.

Yam Cheng, the owner of T-UP climbing gym, helped us find Fusheng Precision, a company ranked among the top 100 Taiwan exporters. With 11,000 employees, Fusheng Precision specializes in titanium alloy products for the automobile, aviation, and medical industries, such as automotive turbocharger turbines, golf club heads, and other products. Significantly, Fusheng also makes custom cast and forged titanium products. With such capabilities, and a reputation for quality assurance, producing a titanium climbing bolt would not be difficult.

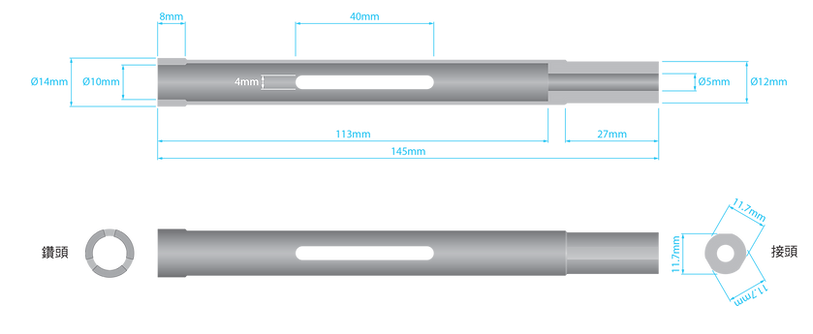

錨栓的設計,最基本當然是要符合歐盟對於攀岩錨栓的規範:EN959 標準 (感謝博文提供相關資訊)。不過,EN959 只是最低標準,因此我們需要在這標準上再強化我們的需求:增加抗腐蝕的耐用度。抵抗腐蝕有許多手段,除了材料選擇外,還可藉由設計來進行加強。鈦只是相當不易生鏽,並不是真的不會鏽,這個世界上目前還不存在「完全不會生鏽」的金屬或合金。

從設計上的強化,至少有兩個方向可下手:其一,一體成型,即減少bolt總體的表面積,降低鏽蝕反應速率,而且不會存在焊接等可能造成易腐蝕的弱點。加上是以鑄造方式成形,不會存在如彎折等方式所殘留的內應力 (造成鏽蝕的原因之一);其二,加粗直徑,越粗就撐越久。基本上是以「過頭」的方式,來提高三四十年後所能保有的強度。大部分型號的鈦金屬只要 8mm,即已超過 EN959 的強度要求,市面上就有一款鈦合金錨栓是以 8.8mm 的鈦條彎折製成。廠商有成本考量,每多粗一點,成本就更高一些,售價就得上調。鈦合金錨栓的售價在市場上的接受度已不高,因此廠商也必須在其間取得平衡。然而,我們的成品並不販售,因此在這方面有更多彈性。我們的鈦合金錨栓設計直徑最後決定以 12mm 為基調,因為除了強度考量外,我們也希望能夠為未來保留沿用舊孔的機會。當然,設計上還有許多其他考量,比如 P 型、T 型與 U 型的決擇:由於 U 型要鑽兩個孔,因此我們決定不考慮;而 P 型,部分方向受力較強,部分方向受力卻會較弱;因此,最後我們決定採用可多方向受力的 T 型做為版本。

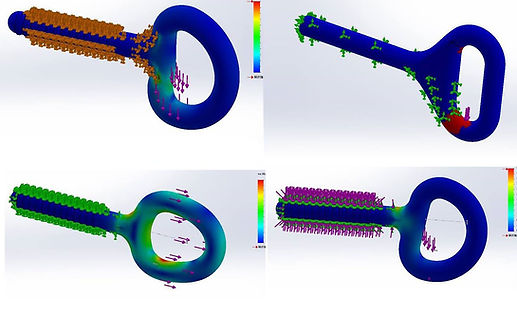

整個設計過程是在不斷的討論、檢討中改進,一點一滴逼進最適合的平衡點。其中,不可或缺的另一位關鍵岩友,即是熱心的小傑;發揮了他機械專家的本領,為我們進行一次又一次的電腦應力分析,並接下繪製3D檔案的工作。另外,也感謝岩友 Jamy 提供我們 3D 列印的服務。

In designing a bolt, a primary consideration is that the bolt must conform to international safety standards, particularly EN959 (special thanks to Bowen Cheng for providing a copy of EN959). However, EN959 should be considered merely the minimum standard, and additional features, particularly the bolt’s ability to resist corrosion, must also be taken into account. There are a variety of approaches to optimizing the corrosion resistance of a bolt design. In addition to the type of material selected, bolt design is also a key factor. Even titanium alloys are not truly immune to corrosion, but instead achieve relatively high levels of corrosion resistance. In fact, there is no known material that is completely immune to corrosion.

Beyond meeting the EN959 standard, it was determined that the ideal bolt design should meet two additional objectives. First, the bolt should be of a one-piece design, in order to minimize total exposure area, thereby slowing the corrosion reaction process, if any; and, due to the cast, one-piece design, reducing or eliminating the residual internal stress that occurs in forged, bent designs and that is known to be one of the contributing factors of SCC. Second, the bolt’s diameter should be as large as practical, so that it can last longer, following a principle of ‘over-designing’ such that a bolt can last at least 30 or 40 years and its strength will remain intact. Most titanium bolts currently on the market are formed of bent 8.8 mm stock. This is done mainly due to cost considerations: larger stock is more costly to make and results in a pricier product. However, we decided to make our titanium bolt 12 mm, for two reasons: first and obviously, we want a stronger bolt, and second, we want to make the bolt hole reusable, in order to simplify any replacement, of even the titanium bolt, that might need to be performed by future climbers. There are other considerations as well: for example, there are several popular configurations of glue-in bolts: P-shape, T-shape, and U-shape. A U-shaped bolt requires two drilled holes, doubling the damage to the rock wall; therefore, U-shaped designs were eliminated from consideration. Meanwhile, a P-shaped bolt has problems in handling different loading directions, and was therefore also dropped from our consideration. Finally, only the T-shaped bolt, with its ability to withstand multi-directional loading forces and its need for only one hole, was determined satisfactory for our needs.

The design process benefitted from continuous discussion and idea exchange among many local climbers as we worked toward a consensus. During the discussions, Xiao Jie, an active climber and important contributor who is familiar with mechanical engineering, performed the necessary stress analysis, shared the results, and helped finalize the computerized 3D graph of the titanium bolt that has existed today. Special thanks also go to Jamy Chen, who made the 3D print of the bolt possible.

由於我們並不打算販售,因此不需花費資源取得可於歐盟販售的 CE 認證標誌,僅需達到其自我認證標準即可。不過,章醫生認為我們開發鈦合金錨栓的目的,是為了確實提高使用壽命,所以不能像一般廠商只進行 EN959 或 UIAA 所規範的強度測試,我們還必需對樣品加做「銅鹽加速醋酸鹽霧腐蝕」,以模擬50年的海岸環境腐蝕 ( 1 小時約等於 40 天的海岸曝露天數),以及針對應力腐蝕的「沸騰氯化鎂腐蝕測試」,完成這兩項重要的指標性測試後,還必須對「每一支錨栓」施以「X 光孔隙率檢測」,以及「12kN 剪力品管測試」,通過所有測試的錨栓才能安裝在岩壁上供岩友使用。

在經過一年多的努力後,我們終於在 2019 年初完成所有鈦合金錨栓的品管測試,正式擁有專為龍洞量身打造、臺灣自製的鈦合金錨栓。這是團隊成員與臺灣攀岩社群的心血結晶,同時也為臺灣攀岩界寫下歷史新頁。

As mentioned earlier, the Taiwan-made titanium bolt was not intended for sale, so we decided not to acquire the costly CE certification (or, for that matter, the UIAA certification). Nevertheless, as Dr. Chang asserted, the main goal of making the titanium bolt on our own was to assure its lasting usability in Long Dong’s corrosive environment. To achieve such goal, we sample-tested the titanium bolt under ASTM B368, an accelerated test simulating a coastal environment (an hour under test simulating 40 days of natural coastal climate conditions), as well as under ASTM G36, the test specifically testing for SCC resistance. After passing these two tests, ALL titanium bolts must pass the X-ray interstitial examination as well as a pull-test of 12kN to assure their quality, before being deemed qualified for installation on Long Dong’s cliffs.

By early 2019, all testing of new bolts was completed, and Long Dong was finally able to receive installation of custom Taiwan-made titanium bolts. This was the successful result of the collective endeavor by the Taiwanese climbing community as a whole, and ever since, a new era of the rock climbing history in Taiwan has begun to unfold.

銑洞計畫

COREDRILL

PROJECT

由資深岩友吳彥儀於2015年開發,為了能有效減少未來在岩壁上鑽設新孔洞的數量,試圖發展一連串工序,並利用空心鑽頭將老舊錨栓的桿芯完整銑出,便可再重複利用舊孔洞設置新錨栓。然而因現有人力、技術、以及設備門檻,導致銑洞成效無法提升,因此本計畫目前暫停中。

This project was initiated by the senior climber, Yan-yi Wu, in 2015. Its purpose was to reduce the need to drill new holes when replacing old bolts. Wu had investigated and attempted various methods in order to core-drill out the existing bolt so that after the bolt had been core-drilled out, a new bolt could be installed in the existing hole. Due to the shortage of manpower and the lack of specialized tools and experience, this approach was largely ineffective and inefficient. As a result, this project is currently on hold.

讓路線長命百歲

ROUTES TO LAST

FOREVER

就像錨栓一樣,路線也有壽命。一般而言,每條路線第一輪裝設的錨栓,都會選擇設置在最理想的位置。然而,當金屬設備隨著時間逐漸腐鏽而損毀,現有設備與技術又無法將老舊錨栓取出時,第二輪更新的錨栓,就只能退而求其次選擇設置在次好的位置。這樣的遞減效應在環境嚴苛的濱海岩場如龍洞,尤其明顯;例如更新頻率最高的音樂廳熱門路線,如今已經歷了二輪更新,目前在岩壁上的錨栓已是第三代,如果我們再不開始重視這問題,遲早有一天,我們將再也無法在路線上找到設置新錨栓的位置,進而被迫放棄更新,只能留下千瘡百孔的岩壁。

為此,除了研發強度更高、更耐久的臺製鈦合金錨栓之外,我們也認真思考重複使用舊孔洞的可能性,首先,便是孔徑問題;過去龍洞常用的錨栓款式使用的孔徑多為 12mm 左右,所以我們決定將臺製鈦合金錨栓的桿芯直徑定為 12mm,如此一來,便可利用外徑 14mm 的空心鑽頭,將舊孔洞裡的老舊錨栓桿芯完整鑽出後,便可再重新利用舊孔洞。

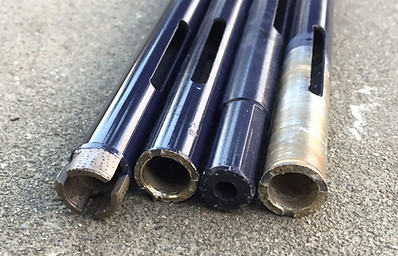

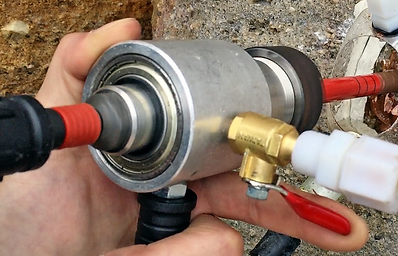

接下來,便是最複雜,難度也最高的問題:將老舊錨栓的桿芯取出。由於市面上販售空心鑽頭的廠商極少,適合我們規格需求的選擇更是寥寥可數,因此,除了知名工具機品牌 HILTI 生產的「Diamond core bit DD-C 14/150 T2」之外,我們也委請資深岩友王爸依照我們的規格需求訂製了一款臺製空心鑽頭,以及相應的注水轉接頭套件。

Like bolts, every climbing route has a particular lifespan. When a route is first bolted, the bolts are generally installed in the best places. When the first set of bolts becomes corroded and dangerous, the replacement bolts may be limited to installation in less ideal places if the first-round bolts cannot be extracted and their holes reused. This cycle could be repeated in a third round of bolting, and the process could continue, resulting in degradation of the quality of the route as less and less ideal bolt locations are used. Such route quality deterioration can be seen at Long Dong due to its proximity to the sea. Looking at what is probably the most-visited area, Music Hall, where some routes now have a third round of bolts, one can observe evidence of the evolution of the routes there. If this issue is ignored, one day we may find ourselves with no place to install new bolts and the only option left would be no bolt replacement at all.

So, in addition to the development of the titanium bolt, we have thoroughly explored the possibility of reusing the existing bolt holes. One issue was selection of the proper bolt diameter. Because the majority of existing bolts at Long Dong were 12 mm in size, we designed the titanium bolt to also be 12 mm, in the hope that we could use a 14 mm core drill to extract the old bolts and reuse their holes, as described above.

But the difficulty didn’t stop there. The next step of core-drilling and extracting the old bolts turned out to be a huge challenge. Small-diameter core-drilling bits were so hard to find, particularly of the 14 mm size that we needed, that we had only Hilti’s diamond-core bit DD-C 14/150 T2 and a Taiwan-made diamond-head bit, designed and donated by another active climber and contributor, Jing-Jung Wang, to experiment with.

不過,即便有了難以取得的空心鑽頭,一連串更艱難的挑戰才真正開始。首先,由於銑洞是一項需要耗費大量時間鑽芯的工序,因此,資深岩友吳彥儀特地設計了一組能夠在岩壁上長時間工作的施工架;另外,由於空心鑽頭在長時間的摩擦下會產生高溫,進而影響其強度與耐用度,因此他也設計了一套能夠帶上岩壁使用的循環水冷系統;除此之外,他也為銑洞的第一個步驟,同時也是最麻煩的步驟:桿芯定位,發展出一套標準化的工作程序,並開發相應的定位模具與輔助器材。

然而,在經過資深岩友吳彥儀長時間不斷地嘗試與改進,投入大量的心力並研發相關設備後,銑洞的成效依舊無法有效提昇,顯示以目前市面上可取得的設備與技術,以及我們可投入的人力與資源,暫時還無法以銑洞的方式達到「重複使用舊孔洞」的最終目標,因此,我們只能決定將銑洞計畫暫時擱置,期待未來能夠在技術或設備上取得新的突破和機會,讓我們能有機會再度重啟這項計畫,並且再也不必在岩壁上鑽出新的孔洞。

So we had a stock of core-drilling bits. But other challenges arose, one after another. First came the issue of a reasonable working station. Core drilling is a slow process and therefore requires long periods of working while up on the cliff, and it is difficult for anyone to work for extended periods of time while hanging in a harness. To resolve this issue, Wu designed and built a ‘frame’ to allow greater comfort while working on the cliff. Next came the problem of cooling the drill bits, that is, to remove the heat accumulated by core drilling, and particularly the problem of supplying fresh water for cooling while working high above the ground. Wu also resolved this problem, by designing and building a self-sustaining circular freshwater cooling system. Finally, the issue of pinpointing and fixing the starting position of core drilling, to prevent the drill bits from contacting the bolt and breaking. This problem was also solved, again through Wu’s ingenious design and numerous trials.

Still, the core drilling remains a very slow and mistake-prone process, even after so many issues have been resolved here at Long Dong. In fact, small-diameter core drilling of climbing bolts is still in experimental stages at climbing areas around the world. Without better drill bits, more convenient cooling systems, and easy-to-use and precise pinpointing mechanisms, it’s very likely that even after successful extraction of the old bolt, the core-drilled hole is unusable. Finally, after all the effort to improve the system, using and even improving on the equipment currently available, it was decided that the core-drilling method was not efficient enough to fulfill our goal of reusing the old holes. Therefore, the Core Drill Project has been put on hold for now. If new and more effective tools are introduced in the market, we’ll reopen the Project and continue to experiment.

龍洞攀岩資料庫

LD

DATABASE

由資深岩友康明哲於2012年開發,蒐集並彙整龍洞岩場所有錨栓的相關資訊,如廠牌、型號、款式、材質、設置日期等,將所有路線與錨栓相關資訊彙整統計,製成有史以來最詳盡的龍洞路線資料庫,供岩友與工作人員查詢。目前正在進行全面改版,因此手機版 APP 停用中,但網頁版仍可使用。

The Long Dong Database was established by the veteran Long Dong climber, Kant Kang, in 2012. The database stores updated information on almost every bolt at Long Dong, including brand, model, type, material, and installation and replacement dates. It is the most comprehensive database of its kind, and can be freely accessed by anyone. The database is currently under reconstruction, so its mobile app is currently unavailable, but the desktop app is available.

安全不能賭

SAFETY

IS TOP PRIORITY

為了解決攀岩者經常難以取得路線上的錨栓安全相關資訊的問題,資深岩友康明哲於 2012 年獨力開發了 Climbio.org 攀岩資料庫平台,蒐集並彙整全臺灣各大天然與人工岩場的相關資訊,其中也當然也包含龍洞岩場,除了為岩友提供每條路線的基本資訊外,也包含路線上每一支錨栓的廠牌、型號、款式、材質、設置日期等重要資訊,建立有史以來最詳盡的龍洞路線資料庫,讓岩友與工作團隊可隨時取得最新的錨栓相關資訊。

下列為目前龍洞岩壁上現有的各款錨栓統計資料:

304

Stainless Steel

304 - Fixe

304 - Petzl - Collinox

304 - Petzl - Long Life

304 - Expension Bolt

68

30

6

7

316

Stainless Steel

316 - Fixe

316 - 台製

74

1196

Ti

Titanium

Ti - Titan Climbing - Eterna

Ti - Titan Climbing - U形

Ti - Ushba - Tortuga

Ti - 台製

235

168

8

209

根據統計,龍洞目前僅存的 111 支 304 不鏽鋼錨栓,都分佈在第一洞少數較冷門,或難度較高的路線,施工上相對困難,需要更多的人力與更繁複的工作規劃,短期內將無法全面更新,因此,在第一洞攀岩的朋友們,使用錨栓時請特別注意其廠牌、款式、材質、以及外觀狀況,若有嚴重鏽蝕或任何異狀,還請盡快通知我們。

而在經過多年的使用後,我們決定將更多的岩場相關資訊,如救援計畫、生態保育、以及岩場清潔活動等相關資訊一併整合,成為更完整的龍洞岩場資料庫。同時也計畫重新設計一般使用者與各計畫工作小組成員的使用介面,讓資料庫的資料更新機制能夠更完備、更全面、也更即時。由於這是一項繁複且工程浩大的計畫,需要更多的專業人力與相關資源如程式編寫、手機 APP 設計、資料庫建構、網站架設等。因此,若您有能力且有意願提供任何形式的協助,隨時歡迎您與我們聯繫。

As of this writing, there are 111 304-grade stainless steel bolts still installed at Long Dong, all of which are located at First Cave, on seldom-visited or difficult-to-access routes. Replacing and removing these 304-grade bolts is complex work, so these bolts will likely remain in place for some time longer. Please exercise caution when visiting First Cave, and pay special attention to the brand, type, material and appearance of any bolts you plan to use. If you encounter any bolt that appears corroded or otherwise abnormal, please let us know as soon as possible.

After using several different data platforms and media to store Long Dong-related data over the past few years, we are now planning to integrate all such information, including that of the Rescue Project, the Conservation Project, and route-related information, into a single, comprehensive, user-friendly Long Dong Database. This is a huge task and requires volunteers and expertise. If you have knowledge of computer programming, mobile app programming, database construction or website design, please contact us. We need you!